Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

The load cell is a device that converts the mass/weight signal into a measurable electrical signal output. According to the conversion method, Load Cells can be divided into 8 types: photoelectric, hydraulic, electromagnetic, capacitive, magnetic pole change, vibration, gyroscope, resistance strain, etc. Among them, the resistance strain is the most widely used one.

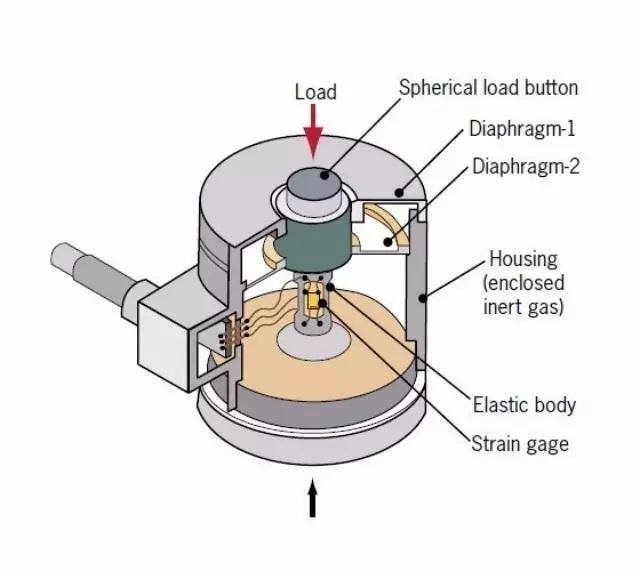

Working principle of load cell

The load cell uses a metal resistance Strain Gauge to form a measuring bridge, and is made by the principle that the metal resistance wire stretches and becomes thinner under the action of tension, and the resistance increases, that is, the effect of the change of the metal resistance with the strain received. The load cell is a conversion device used to convert a weight signal or a pressure signal into a power signal.

The construction principle of the load cell is that the metal resistance has the property of obstructing the flow of current. Generally speaking, the more slender the metal wire, the greater the resistance value. When the metal resistance wire is stretched and contracted by an external force, its resistance value will increase or decrease within a certain range. Therefore, if the metal wire (or film) is tightly attached to the measured object, when the measured object expands and contracts under external force, the metal resistance wire (membrane) will expand and contract proportionally, and its resistance value will also change accordingly. The load cell is to paste the metal resistance strain gauge on the metal weighing beam to measure the weight signal.

Application range of load cell

With the development of the intelligent age, load cells have been applied to almost all weighing fields, realizing accurate weighing of materials. Especially with the emergence of microprocessors and the continuous improvement of industrial automation technology, load cells have become a necessary device in process control. From the weight measurement of large tanks and hoppers that could not be weighed before, and the measurement and control of crane scales, automobile scales, etc., to the batching system for mixing and distributing a variety of raw materials, automatic detection in the production process, and control of the powder and granular material feed volume, etc., Have applied the load cell.

At present, load cells are mainly used in various electronic weighing instruments, industrial control fields, online control, installation overload alarms, material testing machines, and other fields, such as electronic truck scales, electronic platform scales, electronic forklifts, dynamic axle load scales, electronic hook scales, etc., Electronic pricing scales, electronic steel scales, electronic rail scales, hopper scales, batching scales, filling scales, etc.

How to choose the load cell correctly?

Our main consideration is the actual working environment of the sensor, because this is related to whether the sensor can work normally, its safety and service life, and even the reliability and safety of the entire weighing instrument.

On the one hand, it depends on the type of weighing and installation space to ensure proper installation and safe and reliable weighing; on the other hand, the manufacturer`s recommendations must be considered. For sensor manufacturers, it generally specifies the force and performance indicators of the sensor. , Installation form, structural form, the material of elastic body, etc., for example, aluminum alloy cantilever beam sensor is suitable for electronic price calculation scale, platform scale, case scale, etc., steel cantilever beam sensor is suitable for electronic belt scale, sorting scale, etc., steel Bridge sensors are suitable for railway scales, truck scales, etc., and column sensors are suitable for truck scales, dynamic railway scales, and large-tonnage hopper scales.

Under normal circumstances, the high-temperature environment will cause problems such as melting of the coating material, open solder joints, structural changes in the internal stress of the elastomer, etc.; dust and humidity will cause short-circuit effects on the sensor; in a highly corrosive environment, it will cause the sensor elastomer Damage or short-circuit phenomenon; electromagnetic field will interfere with sensor output. Therefore, under the corresponding environmental factors, we must select the corresponding load cell to meet the necessary weighing requirements.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.